Production tools are downhole tools and components designed to enhance the efficiency and effectiveness of the rod lift system. These include what many consider standard operating equipment such as on-off tools, TACs, and mud anchors, as well as newer innovations such as the Gas Separator and Slimhole TAC.

The installation of a tubing anchor is a common and beneficial addition to every rod lifted well. Maintaining pull tension on the tubing string greatly reduces tubing movement caused by cyclical loading created during normal rod lift operation. The reduction of tubing movement enables the pump to consistently make a full stroke and maximize the efficiency of the entire rod lift system.

Having been around for decades and commonly known as a Baker style, the Type B tubing anchor may be placed anywhere within the tubing string and set to anchor to the casing wall. However, the most common placement is below the sucker rod pump, typically with a tubing sub between the two in order to allow space for a gas anchor on the bottom end of the pump.

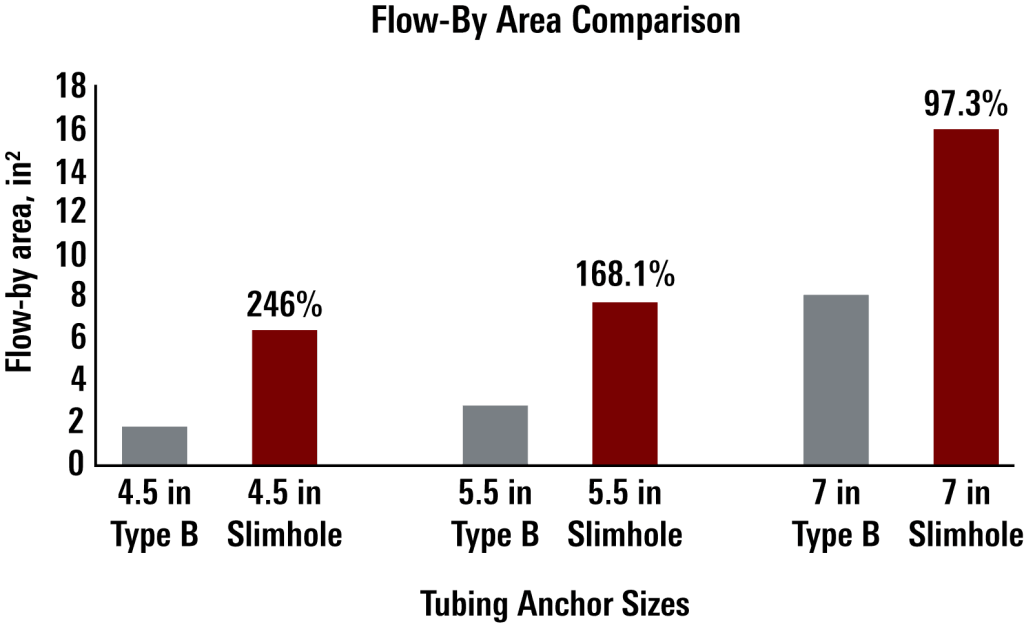

In contrast to a standard anchor, the Don-Nan Slimhole Tubing Anchor can be deployed at any point in the well in relation to the perforations. The improved design minimizes solids buildup in the anchor, and the smaller OD drastically improves gas flow past the anchor.

The Don-Nan Gas Separator is a packer-style separator designed to separate free and entrained gas from wellbore fluids before they reach the pump intake. The separation of gas from production fluid minimizes gas interference and gas breakout in the downhole rod pump, improving rod lift system efficiency.

When a seating nipple for an insert pump is not present in the tubing, the Don-Nan insert pump anchor serves the dual purpose of anchoring the pump and packing off the fluid production string.

For wells using fiberglass sucker rods, the Don-Nan Shear Tool is run above the pump to enable easy retrieval of rods. In the event that the predetermined amount of tension is exceeded when pulling the sucker rods, the Don-Nan shear tool’s tensile element will separate, allowing the rods from that point and up to be easily retrieved. The remaining rods and pump can subsequently be pulled from the well, ensuring the integrity of the rods.

The Don-Nan on-off tool connects to or disconnects from a rodstring, at any point, based on the location of the tool in the rodstring. The tool is attached directly to the rodstring where

the operator wishes to make the disconnection. The tool is then disconnected by turning the rodstring and picking up. The tool is connected by setting down weight on the bottom latch section and rotating the rodstring in the latch direction.

The slotted mud anchor is used to gravity separate gas and solids from production fluid. On the start of the upstroke, fluid, gas and solids are pulled into the slots and down towards the intake of the gas anchor. When the pump begins the downstroke, fluid goes still in the mud anchor and the gas will migrate through the fluid and exit the slots, up the casing annulus. During the entire procedure, solids will fall to the bottom of the mud anchor past the intake of the gas anchor. The slotted mud anchor permits fluid to rise to a lower pressure area and fall back to pump suction. Fluid velocity is then stabilized after the fluid enters the mud anchor, improving efficiency of the pump. The purpose of the attached dip tube is to lower pump intake below the slots in the outer body.

Enhanced from conventional dump valve models prevalent in the industry, the LUFKIN Dump Valve has undergone continuous development to reduce the chance of unscrewing valve connection in the event of any pump tagging. This valve serves as an alternative solution for tubing drainage during pump removal and maintenance. When integrated into a rod pump assembly, it allows for remote opening and closing from the surface. Additionally, it can be utilized in conjunction with various tubing drains or burst joints in the tubing string, offering an alternative method for draining the production tubing prior to pump extraction.