Slickwater Refrac’d Vertical Wells customized BHA mitigates fine-sands-production issues and increases MTBF 10-well study, estimated savings $900K

In the Permian Basin, wells producing from unconsolidated formations often produce massive amounts of sand. In a similar manner, hydraulically fractured wells can produce substantial quantities of proppant. The produced solids and fines can damage pumps and production equipment, greatly reducing equipment performance, increasing maintenance costs, and decreasing or even stalling production.

Customer Challenge:

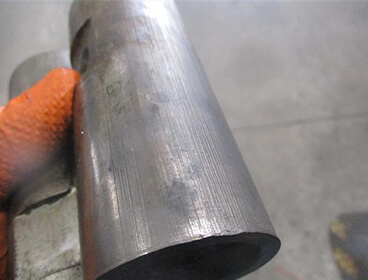

An operator in Eddy County, New Mexico was combatting sand problems after performing a slickwater refrac in a vertical well. While running a rod pump and desander, the operator had to contend with massive amounts of 100-mesh sand. At 62 days, the operator was forced to halt production and schedule workover activity. Image 1, 2 and 3 depict the damage to the pump.

Don-Nan Solution:

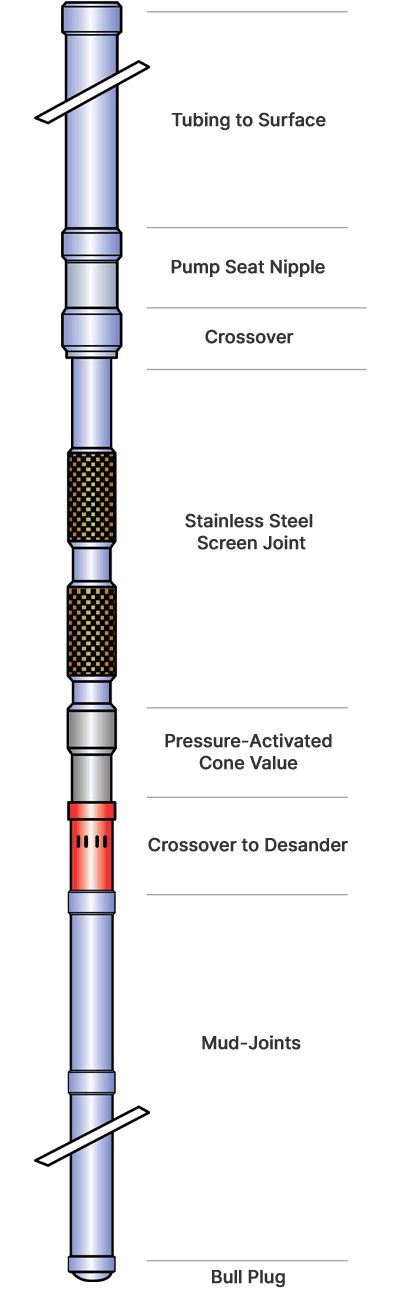

The Don-Nan Solutions Team reviewed PumpTrakTM performance records with the operator. The team devised a solution to reduce sand production, extend mean time between failure (MTBF), and improve production. The Solutions Team recommended boosting the bottom hole assembly (BHA), with 3D screen technology, a single stainless steel-wool screen joint in combination with a pressure-activated cone valve assembly. Refer to Figure 1 for the BHA Schematic with 3D Screen Technology. The patented stainless steel-wool screen creates a unique 3D filtration system to keep a wide range of particle sizes from entering the pump. Using highly permeable compressed stainless-steel wool wrapped around a perforated base pipe and protected by a perforated shroud, the screen’s non-uniform, angular pores are hard to plug, delivering an open flow area of 40 percent. The pore size diversity ranges from 15 to 600pm. The collection of larger particles around the screen creates an enhanced permeability zone with a higher flow capacity to yield greater productivity. The screens are robust and corrosion-resistant, providing structural strength and stability during deployment and production. A pressure-activated cone valve inserted below the screens was installed to extend the life of pumps and equipment. As sand bridges the annular space between the casing wall and screen, it chokes fluid flow through the tubing, increasing differential pressure between the tubing and annulus. When this pressure reaches a pre-set limit, the cone valve opens to allow flow to continue through the pump. With fluid once again flowing, the resulting changes in pressure and flow force the buildup of solids to fall away from the screen. This reestablishes flow through the screens, dropping differential pressure, and closing the cone valve. This cyclic process repeats as needed, with no intervention required.

Figure 1: BHA Schematic with 3D Screen Technology.

CUSTOMER SUCCESS:

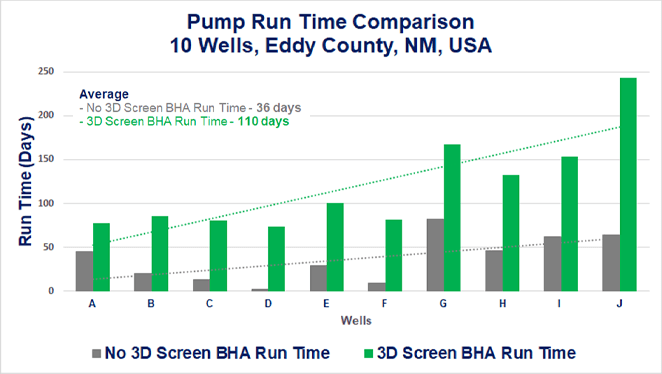

For the 1st well, with the customized BHA with 3D screen technology installed, the pump run time more than doubled–from the previous 62-day mark, to 153 days. Based on these results, the operator subsequently installed the system in at least 9 wells throughout the field. In each well, the 3D filtration system continues to replicate the consistently high run time observed on the 1st well. For the 10 well study, initial pump run time was as low as 10 days, the average pump run time increased from 36-days to 110-days, a documented 3 fold increase. The operator realized estimated $900K savings in workover costs. These wells are still on-production with no service interruptions.*

* 2/5/2022

Chart 1: Results of 10 Well Field Study: 3D Screen Technology. Average pump run time tripled.