Total Cost

Total Cost

Power

Power  Mean Time

Mean Time  Efficiency

Efficiency

Production

Production

Each well has its own set of production characteristics and constraints.

Pump speed, perf depth, motor HP, rod stress, max torque, pump capacity, rod string diameter, and more… We need to make it all translate into maximum production, lower power consumption, and extended uptime—And all at the lowest cost possible.

It’s really not that difficult—when SROD, intelligent rod pump design software leads you through the process.

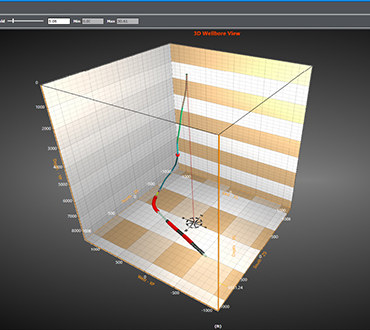

Upload a well’s deviation survey to model the wellbore configuration within the SROD 3D viewer. Enhance your view by adding perforations, completion equipment and tubular data.

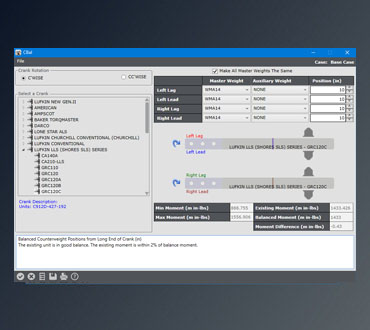

The SROD system will guide you through the design process as you input pump and tubing parameters, rod-string type and taper particulars, pumping unit size, crank information, motor size, and more.

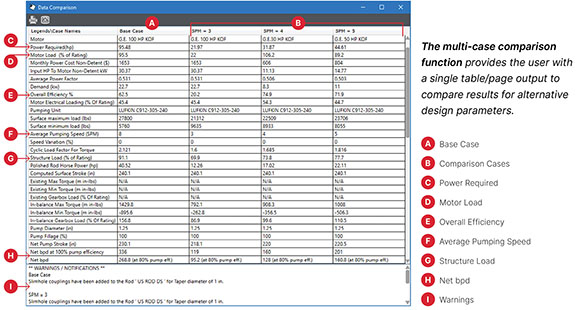

Once you’ve entered all input parameters, the SROD system generates a base case and delivers a single-page report on key components and performance capabilities.

Rod pump design requires careful consideration of performance versus costs, and economics versus efficiency. SROD predictive design lets you weigh the cost of each equipment option. The SROD’s multi-case comparison function presents a single-page tabulation for comparing various equipment selections against alternative design parameters—thus optimizing your pump design from top to bottom.

With nearly 100 years of Sucker Rod Pumping history, Lufkin delivers both expertise and equipment to help you get the most from your asset.

For a personalized demonstration and trial license, contact the SROD licensing support team.

For technical issues, problems or questions, contact the SROD technical support team for help.

For all other inquiries, contact the SROD sales team.