Results of a 6 month head to head test with the LUFKIN ES Coupling versus the leading competitive corrosion service coupling. Note the significant reduction in corrosion on the LUFKIN ES Coupling.

Leading corrosion service coupling

LUFKIN’s ES Coupling

SPECIALLY FORMULATED WITH ENHANCED PROPERTIES

Our patent pending ES coupling is designed and manufactured for use in critical service applications, providing enhanced fatigue performance and corrosion tolerance in tough operating environments. Our modified micro-alloyed steel, unique thermal processing, and unparalleled precision machining increases run times and reduces costs in your toughest, critical applications. With excellent impact properties and specially selected alloy elements, this coupling will help improve reliability, run times and reduce costs in your most problematic wells.

MANUFACTURED TO THE HIGHEST STANDARDS

LUFKIN Rods’ extremely accurate precision CNC lathes and our unique manufacturing approach ensures the threads are concentric with the outer diameter for the most concentric wall thickness throughout. This eliminates stress concentrations due to eccentric wall thickness.

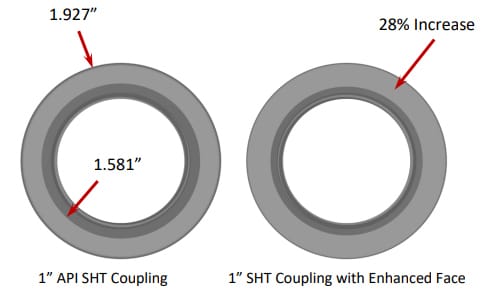

LUFKIN’s couplings are manufactured with an enhanced face that provides maximum contact area between the coupling face and the sucker rod pin shoulder. This improved design fosters consistent circumferential displacement (CD) and preload stress values during makeup, helping to reduce connection related failures. In addition, all our couplings are furnished with cold formed threads that provide additional strength and fatigue resistance. All ONYX couplings are manganese phosphate coated for corrosion protection, antigalling and lubricity.

AMERICAN MADE—LUFKIN QUALITY

LUKFIN couplings are manufactured in the only privately owned and operated sucker rod plant in the USA. Our ONYX products are sourced an manufactured domestically, and our advanced manufacturing processes ensure the highest quality possible. Our automated system continually monitors each step to ensure consistently high quality from start to finish. LUFKIN’s quality control is unmatched throughout the industry.

ES COUPLINGS—SPECIFICATIONS

MECHANICAL

- Material

- Special

- Yield Strength, 2-inch offset, psi

- 85,000 min.

- Tensile Strength, psi

- 95,000 to 115,000

- Elongation, 8-inches, %

- 10 min.

- Reduction of Area, %

- 45 min.

- Hardness HRA

- 56-62

HARDNESS COMPARISON (HRA)

- SM Coupling

- 79 min.

- J-55 Tubing

- 79 min.

- L-80 Tubing

- 2 max.