Wireless Load Cell

Wirelessly transmits accurate polished rod load and position data in realtime

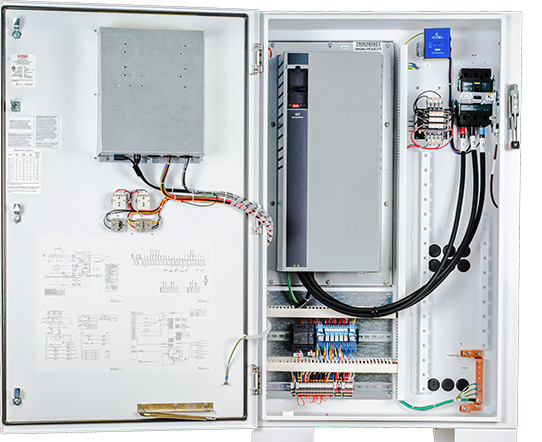

The cable-free Interface™ Load Cell, developed in collaboration with LUFKIN, delivers accurate data for optimal rod lift control. Polished rod load and position data is transmitted in real time to a controller-mounted receiver base station.

ROI Drivers

- Safer installation. Eliminates need for a technician to get inside the pumping unit cranks or near the walking beam to install a load cell cable and position sensor(s)

- Eliminates load cell cable installation and maintenance intensive cable failure-replacement cycle

- Reduced installation time

- Preferred solution for linear pumping units

Features

- Transmission range up to 100ft (30meters)

- Rated for Zone 0 hazardous area

- Onsite battery replacement, LED battery status monitor

- Seamless integration with existing system